Cold Extrusion

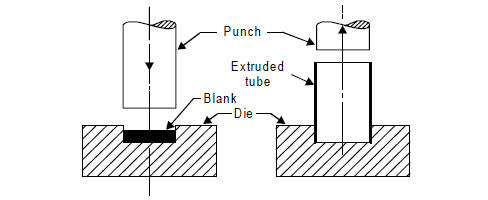

Principle of cold extrusion is similar to that

of hot extrusion, which has been discussed under hot extrusion in section. The dissimilarity is that material in hot working processes should possess

the essential ductility

with out the application of heat. Impact extrusion is also

a cold extrusion process. It is used for making small components from ductile

materials. Impact extrusion process is shown in Fig. Impact extrusion of

material is accomplished where the

work blank is placed in position over the die opening the punch forces the

blank through the die opening causing material to flow plastically around the

punch. The outside diameter of the tube is same as diameter of the die, and the

thickness is controlled by the clearance between

punch and die. Collapsible medicare

tubes and toothpastes etc. are produced using this impact extrusion.

of hot extrusion, which has been discussed under hot extrusion in section. The dissimilarity is that material in hot working processes should possess

the essential ductility

with out the application of heat. Impact extrusion is also

a cold extrusion process. It is used for making small components from ductile

materials. Impact extrusion process is shown in Fig. Impact extrusion of

material is accomplished where the

work blank is placed in position over the die opening the punch forces the

blank through the die opening causing material to flow plastically around the

punch. The outside diameter of the tube is same as diameter of the die, and the

thickness is controlled by the clearance between

punch and die. Collapsible medicare

tubes and toothpastes etc. are produced using this impact extrusion.

|

| Impact extrusion |

Great Post. I am thankful to you for sharing this post. This is very useful for me and as well as for others. Your article is very well written and unique. please keep sharing such posts. Plastic Extrusion Manufacturer