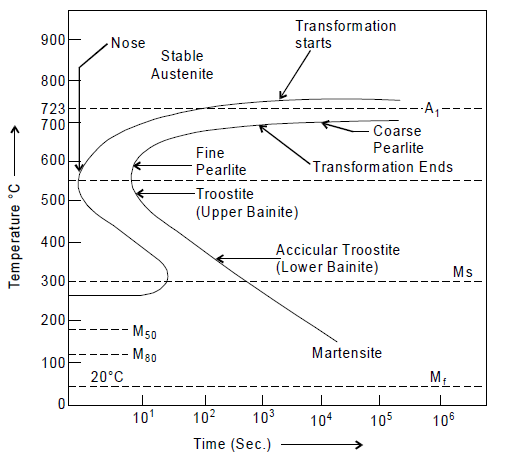

TTT CURVE

The hardness depends upon the structure of materials. The different structure through transformation can be obtained using different cooling rates. The effects of cooling of austenite (steel above 723°C) transformation are depicted in Fig. It can be nicely represented in a temperature, time and transformation (TTT) curve. It is also known as C or S or Bain’s curve. Fig shows TTT diagram for hypo eutectoid steel.

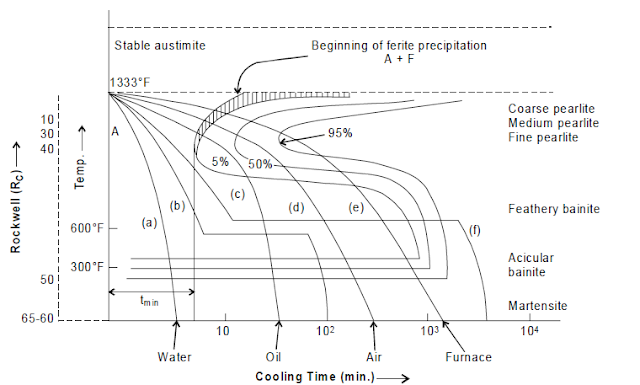

Fig. shows a series of cooling curves which result from different rates of cooling when superimposed on TTT curve. These curves reveal the decomposition of stable austenite existing above critical temperature in various forms during cooling depending upon the cooling rate. The transformation of austenite starts during suitable cooling. The minimum cooling rate required to produce martensite in given steel is determined by the position of the nose of the S curve. The cooling rate required to avoid the nose of the S curve is called the critical cool. Any other cooling rate, faster than to that of the nose of S curve will cause complete transformation of austenite to martensite.

Assume a cooling rate ‘a’ achieved in water, this curve does not cut the nose of TTT curve, and the pearlite transformation does not take place. However the resulting structure at room temperature is martensite. Cooling curve ‘c’ reflects that the cooling rate is slower than water and is in oil still lesser than the critical cooling rate, the curve ‘c’ will result in the micro structure composed of martensite. Curve ‘d’ and curve ‘e’ corresponds to the rate of cooling during normalizing and annealing. The parts of austenite transform to fine and coarse pearlite. The intermediate cooling rate curves ‘f ’ and ‘b’ higher than critical cooling rate results in the structure between pearlite and martensite known as feathery bannite and acicular (needles) bannite. Intermediate cooling rate is achieved by quenching or dipping the austenite at two hot oil baths maintained at different temperature such as in case of austempering (f curve) and mar tempering (b curve). Those special cooling rate will form coarse and fine bainite structure according the level of temperature of quenching.

Transformation of austenite to pearlite depends upon the temperature, time and transformation curve. It relates the transformation of austenite to the time and temperature conditions to which it is subjected. As metal is heated above the critical point austenite will form in the structure of metal if it is cooled slowly with respect to time. The structure wil1 change to coarse pearlite and cementite placeless in a ferrite matrix due to transformation of temperature and hence nuclei thus formed grow rapidly. Such as coarse laminar pearlite is relatively soft and is not very ductile. After this, if slightly faster cooling than above slow cooling is applied to austenite; coarse bainite structure will be formed.