Drill Tool Nomenclature:-

top 500 Mechanical Engineering books

|

| Drill Tool Nomenclature |

|

| Drill tool geometrical terminology |

|

| Drill Tool Nomenclature, Drill Tool Terminology |

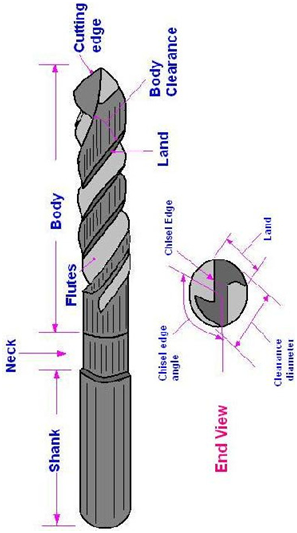

The following are the twist drill elements:

Axis

The longitudinal centre line of the drill.

Body

The portion of the drill extending from its extreme point to the commencement of the neck,

if present, other

wise extending to the commencement of the shank.

if present, other

wise extending to the commencement of the shank.

Body clearance

That portion of the body surface which is reduced

in diameter to provide diametral clearance.

in diameter to provide diametral clearance.

Chisel edge

The edge formed by the intersection of the flanks.

The chisel edge is

also sometimes called

dead centre. The dead centre

or the chisel edge acts

as a flat drill and cuts its own hole in the workpiece.

The chisel edge is

also sometimes called

dead centre. The dead centre

or the chisel edge acts

as a flat drill and cuts its own hole in the workpiece.

Chisel

edge corner

The corner formed by the intersection

of a lip and the chisel edge.

of a lip and the chisel edge.

Face

The portion of the flute

surface adjacent to the lip on which

the chip impinges as it is cut from the work.

surface adjacent to the lip on which

the chip impinges as it is cut from the work.

Flank

That surface on a drill point which extends behind the lip tp the following

flute.

flute.

Flutes

The groove in the body of the drill which

provides lip. The functions of the flutes are:

provides lip. The functions of the flutes are:

To form the cutting

edges on the point

edges on the point

To allow the chips to escape

To cause the chips to curl

To permit the cutting fluid to reach the cutting

edges.

edges.

Heel

The edge formed by the intersection

of the flute surface and the body clearance.

of the flute surface and the body clearance.

Lands

The cylindrically ground

surface on the leading edges of the drill flutes.

The width of the land is measured at right angles to the flute helix.

The drill is full size only across

the lands at the point end. Land keeps

the drill aligned.

surface on the leading edges of the drill flutes.

The width of the land is measured at right angles to the flute helix.

The drill is full size only across

the lands at the point end. Land keeps

the drill aligned.

Lip (cutting

edge)

edge)

The edge formed by the intersection of the flank and face. The

requirements of the drill lips are: 1. Both lips should be at same angle of inclination

with the drill axis, 59o for general work

2. Both lips

should be of equal length

3. Both lips should

be provided with the correct

clearance.

requirements of the drill lips are: 1. Both lips should be at same angle of inclination

with the drill axis, 59o for general work

2. Both lips

should be of equal length

3. Both lips should

be provided with the correct

clearance.

Neck

The diametrically undercut portion between the

body and the shank of the drill. Diameter and other particulars of the drill are engraved

at the neck.

body and the shank of the drill. Diameter and other particulars of the drill are engraved

at the neck.

Outer corner

The corner formed

by the intersection of the flank and face.

by the intersection of the flank and face.

Point

The sharpened end of the drill, consisting of all that part of the drill which is

shaped to produce lips, faces,

flanks and chisel

edge.

shaped to produce lips, faces,

flanks and chisel

edge.

Right

hand cutting drill

hand cutting drill

A drill which cuts when rotating in

counter – clockwise direction viewed on the point end of the drill.

counter – clockwise direction viewed on the point end of the drill.

Shank

that part of the drill by which it is held and driven. The most common types

of shank are the taper

shank and the

straight shank. The taper shank

provides means of cantering and holding the drill by friction in the tapered

end of the spindle.

of shank are the taper

shank and the

straight shank. The taper shank

provides means of cantering and holding the drill by friction in the tapered

end of the spindle.

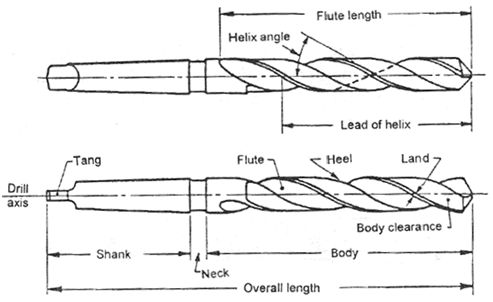

Tang

The flattened end of the taper shank intended to fit into a drift slot in the spindle, socket or drill holder. The tang ensures

positive drives of the drill

from the drill spindle.

positive drives of the drill

from the drill spindle.

Web:

The central portion of the drill situated between the roots of the flutes and

extending from the point toward the shank, the point end of the web or core forms the chisel edge.

The central portion of the drill situated between the roots of the flutes and

extending from the point toward the shank, the point end of the web or core forms the chisel edge.

The following are the linear

dimensions of the drill.

Back

taper

It is the reduction in diameter of the drill from

the point towards the shank.

the point towards the shank.

Body clearance

diameter

The diameter

over the surface

of the drill body which is

situated behind the lands.

over the surface

of the drill body which is

situated behind the lands.

Depth

of body clearance

of body clearance

The amount of radial reduction on each

side to provide body clearance.

side to provide body clearance.

Diameter

The

measurement across the cylindrical lands

at the outer corners of the drill.

measurement across the cylindrical lands

at the outer corners of the drill.

Flute length

The axial length

from the extreme

end of the point to the termination of the flute at the shank end of the body.

from the extreme

end of the point to the termination of the flute at the shank end of the body.

Lead

of helix

of helix

The distance measured parallel to the drill axis

between the corresponding point on the leading edge of the flute in one

complete turn of the flute.

between the corresponding point on the leading edge of the flute in one

complete turn of the flute.

Lip length

The minimum distance

between the outer corner and the chisel

edge corner of the lip.

between the outer corner and the chisel

edge corner of the lip.

Overall length

The length over the extreme

ends of the point and the shank of the drill.

ends of the point and the shank of the drill.

Web (core) taper

The increase in the web or core thickness from the point of the drill

to the shank end of the flute.

to the shank end of the flute.

Web thickness

The minimum dimension of the web or core measured at the point end of the drill.